Karton ist Umweltschutz –

hergestellt ohne

chemische Vorgänge

und recyclebar.

mit Know How und Performance

The production process at Papier Karl - Verpackungswerk Bayern for packaging solutions, cardboard boxes and corrugated cardboard.

Production process - this is how your cardboard boxes are made

We produce your cardboard. Papier Karl has a machine park in which several modern and fully automatic high-performance systems produce packaging products at economical conditions in the best quality. Whether small runs or pallet-wise quantities – we produce according to demand.

Would you like a logo or other imprint on your cardboard? Our packaging plant is also equipped for this purpose and offers various possibilities to present your company or brand on shipping packaging in a sustainable and promotionally effective manner. With a fully equipped production facility, we are able to meet every customer requirement in terms of production technology. Development, manufacturing, production and logistics are connected at just one location and therefore represent a closed process chain.

Heating up the 10t steam boiler

Our corrugated cardboard plant (WPA) is brought to operating temperature using steam (up to 170 °C) and heats the corrugating rollers over which the corrugated cardboard base paper runs. Up to 3-wall corrugated cardboard is possible. Our production hall is heated by condensate recovery and the waste heat from the machines.

Purchasing and preparing corrugated cardboard base papers

Paper Karl sources its paper requirements ecologically and regionally (exclusively FSC). Our paper rolls are fed to the corrugator with the help of an 8t forklift.

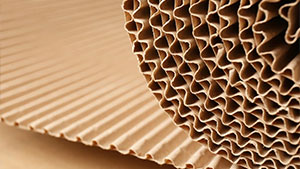

Production of the corrugated cardboard sheet

(WPA, including tear thread or reinforcement tape)

Depending on the customer’s quality requirements, we can produce up to 3-wall corrugated cardboard sheets (format goods) with different calibers (from F to AAC). Several tear threads and reinforcing tapes can also be attached to the corrugator.

Tailoring the benefits

The endless corrugated cardboard web is scored with the creasing and cutting unit and cut lengthways, i.e. across the shaft (wavelength). The cross cutter then separates the endless webs transversely to the direction of travel, i.e. parallel to the wave course (cut length) and divides the web into several panels, which are conveyed beyond or further along two shelves.

In-house laboratory

In our newly equipped laboratory, we test both our corrugated cardboard sheets and our finished boxes for their technical values.

Work-in-Progress (WIP)

Intermediate buffering of the format goods on our fully automated conveyor technology, which serves as a short-term storage area. The transfer cars bring the format goods to our processing machines at the scheduled time.

Feeding and collecting the format goods

The prepared cardboard sheets are fed and automatically drawn into the production machine with the help of a prefeeder.

Flexographic printing

Logos and other motifs are printed here using printing blocks. Multiple colors are possible.

Slotter unit

The slotter unit takes care of slitting and creasing the boxes, as well as punching for handles, for example.

Self-adhesive closure + tear thread

Our processing machines are equipped with SK closures and tear strips – classic e-commerce packaging.

Folding and closing station

Papier Karl offers the possibility of taping, stapling or gluing the common types of fasteners, as well as double fasteners.

Counter stacker with ejection station

The boxes are now automatically counted and bundled as well as prepared for palletizing.

Palletizing and strapping with stretching

The stacked boxes are automatically placed on a Euro pallet, strapped for a better hold and provided with edge protection. The stack can also be stretched at the customer’s request or depending on the box stacking capacity.

Pallets for shipping or storage

The boxes produced are immediately delivered using our own fleet of vehicles. At the customer’s request, we can store items until they are called up.